Welding Training and Certification

We offer the training for certification with hands-on training in our new facility. Or, if you prefer training at your facility, we do that too. Sutton-Garten provides everything welders need for growth in their profession.

• Equipment setup – SMAW, MIG, TIG, Plasma

• Pipe Welding

• Base and Filler Metal overview/selection

• Mild Steel, Aluminum, Introduction to Stainless

• Base Metal cleaning and preparation

• Welding technique/critique

• Certification Prep Courses

• General Fabrication/Art Projects

• Classroom time – 10%, Lab time – 90%

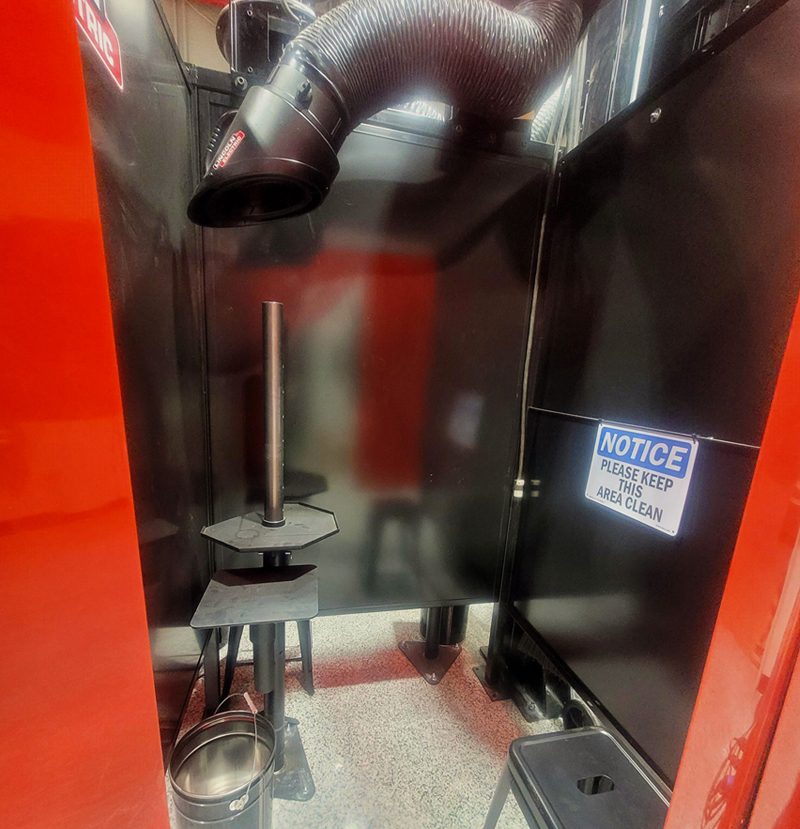

Our recently remodeled 2,000 square foot training facility features 10 new welding booths, fume exhaust equipment and an air-conditioned classroom.